|

45.07: Propeller Install |

|

|

Install

Manuel PDF |

GA-J2B 65" - WHIRLWIND P R O P E L L

E R |

Pre-Flight

Inspection

Perform this inspection before every flight. Before

each flight, carefully examine the propeller blades and hub for

looseness, any signs of damage, excessive wear or any other condition

that would make the propeller unsafe to operate |

|

Initial 50-Hour

Inspection, Annual (100-Hour) Inspections

In addition to the

recommendations for the Pre-Flight Inspection, the propeller and spinner

should be visually examined in detail after the first 50 hours (also

annually and at 2000-Hour). This will require the removal of the spinner

for a detailed examination. |

|

|

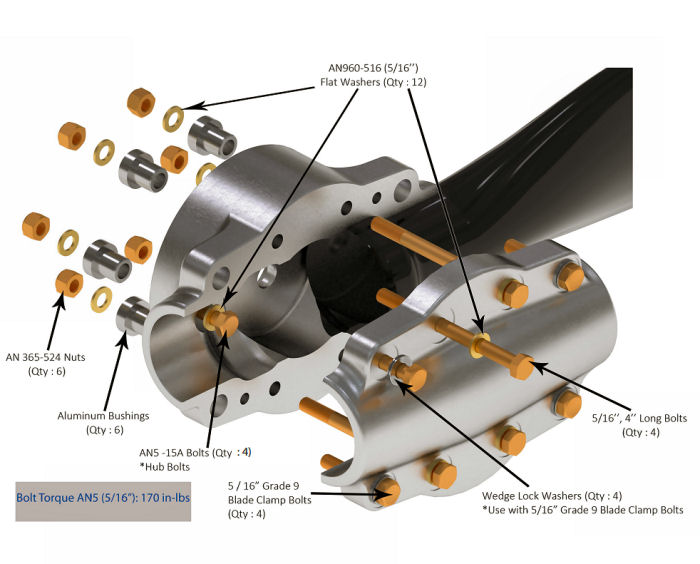

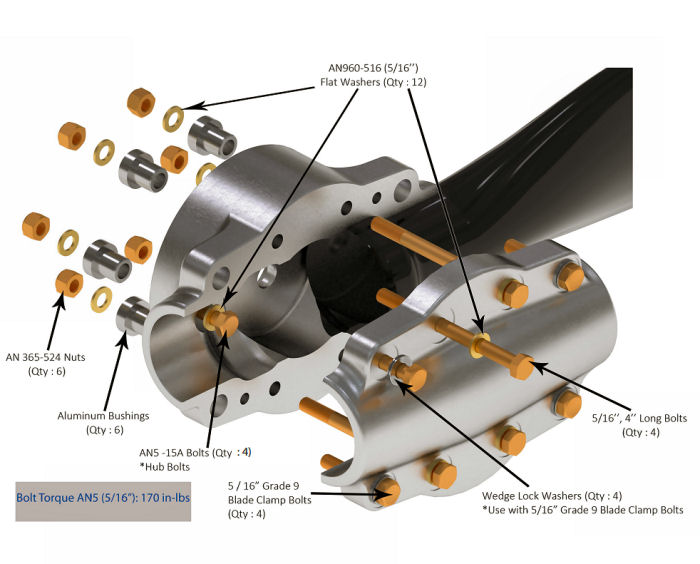

PARTS

| Blades |

2 |

| Hub (forward &

aft halves) |

1 |

| Mounting Bolts,

Long (5/16” x 4”) |

4 |

|

Mounting Bolts, Short AN5-15A (5/16”) |

4 |

| Mounting Flat

Washers (5/16”) |

12 |

| Clamping Bolts

(5/16” Grade 9) |

6 |

| Clamping

Wedge-Lock Washers (5/16”) |

4 |

| AN 365-524 Nuts |

6 |

| Blade Pitch

Paddle |

1 |

|

| |

PITCH NOTES AND LIMITATIONS

The faster the airplane, the higher the pitch setting

that will be required to keep the engine from over

speeding at Wide Open Throttle (WOT). While the

propeller may be structurally operated at any pitch

setting from +14° through +26°, the take off RPM at WOT

must meet the aircraft manufacturer's recommended limits

to ensure safe flight. The propeller RPM should never

exceed the engine manufacturers recommended maximum RPM. |

|

| |

|

|

|

| Page: 45.09 Propeller

Install |

|